Mixing gearbox oil can be a complicated topic, and it can be difficult to know what to do if you’re not an expert. Gearbox oil is used to lubricate and cool the gears in a transmission or gearbox, and it is an essential part of the system. Mixing different types of gearbox oil can have a significant impact on the performance of the gearbox, and it is important to understand the risks and benefits of doing so.

One of the main reasons people mix gearbox oil is to improve the performance of the gearbox. Different types of gearbox oil have different properties, and mixing them can help to create a blend that is better suited to the specific needs of the gearbox. However, it is important to note that not all types of gearbox oil are compatible with each other, and mixing the wrong types can cause serious damage to the gearbox.

When it comes to mixing gearbox oil, it is important to understand the basics of lubrication. Lubrication is the process of reducing friction between two moving parts, and it is essential for the smooth operation of a gearbox. Different types of gearbox oil have different levels of viscosity, and it is important to choose the right type of oil for your gearbox. Mixing oils with different viscosities can cause issues with lubrication, which can lead to increased wear and tear on the gears.

Basics of Gearbox Lubrication

Function of Gear Oil

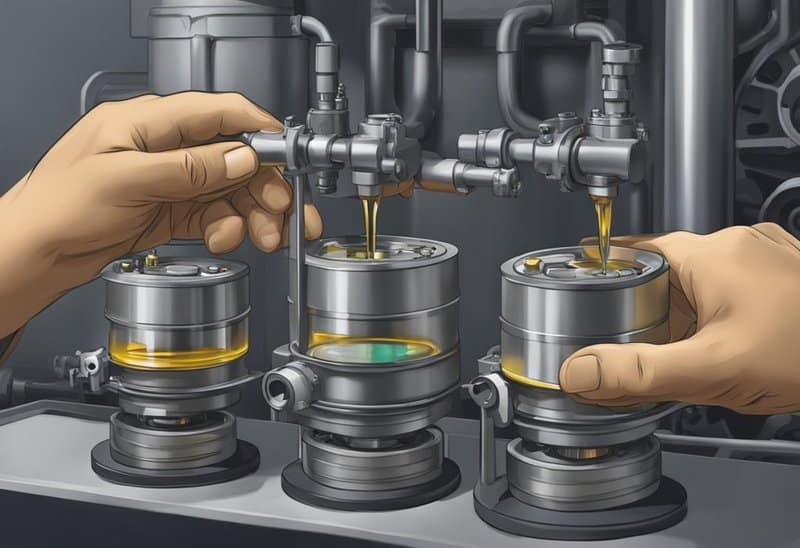

Gear oil is a type of lubricant that is used to reduce friction and wear between the moving components of a gearbox. The primary function of gear oil is to provide a protective film between the gear teeth, which helps to prevent metal-to-metal contact and subsequent wear. Additionally, gear oil helps to cool the gearbox by carrying heat away from the moving parts.

Types of Gear Oils

There are two main types of gear oils – mineral oil and synthetic oil. Mineral oil is derived from crude oil and is the most common type of gear oil. Synthetic oil, on the other hand, is made from chemical compounds and offers superior performance in terms of wear protection, temperature resistance, and longevity. Synthetic gear oils are more expensive than mineral oils, but they offer better performance and longer life.

Importance of Viscosity

Viscosity is an important property of gear oil that affects its performance. Viscosity is a measure of a fluid’s resistance to flow, and it determines how well the gear oil will flow between the gear teeth. If the viscosity is too low, the gear oil will not provide adequate protection, and if the viscosity is too high, the gear oil will not flow properly, leading to increased friction and wear. The viscosity of gear oil is typically measured using the Society of Automotive Engineers (SAE) viscosity rating system, which assigns a number to the oil based on its flow characteristics at a specific temperature.

In addition to viscosity, gear oils may contain various additives that are designed to improve their performance. These additives can include anti-wear agents, corrosion inhibitors, and detergents, among others. The choice of gear oil and additives will depend on the specific application and the requirements of the gearbox.

Overall, proper lubrication is essential for the proper functioning and longevity of a gearbox. The selection of the right type of gear oil, the appropriate viscosity, and the use of additives can all contribute to improved performance and reduced wear.

Gearbox Components and Oil Interaction

Gears and Bearings

In a gearbox, gears and bearings are the most important components that require proper lubrication with gearbox oil. Gears are responsible for transmitting torque and power between different components, while bearings support the rotating shafts and reduce friction. If these components are not lubricated properly, they can cause damage to each other, leading to bearing failure, noise, and reduced efficiency.

Gearbox oil forms a thin layer on the gears and bearings, reducing the friction between them. This helps to prevent wear and tear, which can cause damage to the gears and bearings over time. By reducing friction, gearbox oil also helps to reduce the amount of heat generated by the gears and bearings, preventing them from overheating and becoming damaged.

Seals and Gaskets

Seals and gaskets are used in gearboxes to prevent oil leaks. Seals are used to prevent oil from leaking out of the gearbox, while gaskets are used to seal the joints between different components. If these components are not sealed properly, oil can leak out of the gearbox, leading to reduced lubrication and increased wear and tear.

Gearbox oil interacts with seals and gaskets by forming a barrier between them and the surrounding components. This helps to prevent oil from leaking out of the gearbox, ensuring that all components are properly lubricated. Over time, seals and gaskets can become damaged, leading to leaks. Regular maintenance and inspection can help to prevent this from happening, ensuring that the gearbox remains properly lubricated and efficient.

Oil Performance Factors

When it comes to mixing gearbox oil, there are several factors that can affect the performance of the oil. These factors include temperature, load and speed considerations, and chemical composition and additives.

Temperature Influence

Operating temperature is one of the most important factors that can affect the performance of gearbox oil. The temperature can affect the viscosity of the oil, which in turn affects the oil’s ability to lubricate the internal components of the gearbox. If the temperature is too low, the oil may become too thick and not flow properly, while if the temperature is too high, the oil may become too thin and not provide adequate lubrication. Therefore, it is important to choose an oil that is suitable for the operating temperature of the gearbox.

Load and Speed Considerations

The load and speed of the gearbox can also affect the performance of the oil. If the gearbox is under heavy load or operates at high speeds, the oil must be able to withstand the pressure and provide adequate lubrication. Anti-wear additives can help protect the internal components of the gearbox from wear and tear.

Chemical Composition and Additives

The chemical composition and additives of the oil can also affect its performance. The composition of the oil can affect its viscosity, while additives can improve the oil’s ability to lubricate and protect the internal components of the gearbox. EP additives can help protect the gearbox from extreme pressure and wear, while anti-wear additives can help protect against wear and tear.

In summary, when mixing gearbox oil, it is important to consider the operating temperature, load and speed, and the chemical composition and additives of the oil. By choosing the right oil for the job, you can ensure that your gearbox operates at peak performance and is protected from wear and tear.

Maintenance and Monitoring

Regular maintenance and monitoring of gearbox oil are crucial for ensuring the smooth operation of the machinery and extending its lifespan. This section will cover the oil change procedures, monitoring oil condition, and detecting contaminants.

Oil Change Procedures

Changing the gearbox oil is an essential part of maintenance. The oil level should be checked regularly to ensure that it is at the recommended level. The operating conditions of the machinery will determine how often the oil should be changed. For instance, if the machinery operates in harsh conditions, the oil may need to be changed more frequently.

It is essential to follow the manufacturer’s instructions when changing the oil. The wrong type of oil can cause damage to the gearbox. The oil should be drained and collected in a container before disposing of it properly. The gearbox should be cleaned thoroughly before refilling it with the recommended oil.

Monitoring Oil Condition

Monitoring the condition of the gearbox oil is crucial for detecting any issues before they become severe. Regular oil analysis can provide a status of how the gearbox is performing. Techniques such as temperature, vibration, noise, and used oil analysis can detect any potential problems.

The standard test slate for gearboxes should include viscosity, moisture, elemental analysis, particle count, ferrous density, oxidation, and/or acid number. These tests can detect any contaminants or wear particles in the oil. It is essential to monitor the oil condition regularly to ensure that the gearbox is operating correctly.

Detecting Contaminants

Contaminants such as dirt, debris, and water can cause significant damage to the gearbox. Therefore, it is essential to detect and remove them as soon as possible. Regular oil analysis can detect any contaminants in the oil. The oil should be changed immediately if any contaminants are detected.

In conclusion, regular maintenance and monitoring of gearbox oil are crucial for ensuring the smooth operation of the machinery and extending its lifespan. It is essential to follow the manufacturer’s instructions when changing the oil and to monitor the oil condition regularly. Detecting and removing contaminants as soon as possible can prevent significant damage to the gearbox.

Compatibility and Selection

Choosing the Right Oil

When it comes to mixing gearbox oil, choosing the right oil is crucial. Different types of gear oils have different properties that make them suitable for specific applications. For instance, synthetic gear oils, such as PAO (polyalphaolefin) oils, offer better performance in extreme temperatures and under heavy loads. On the other hand, mineral-based gear oils are more affordable and work well in moderate operating conditions.

To choose the right oil, it is essential to consider factors such as operating temperature, load, and gear type. Referencing the manufacturer’s recommendations can help ensure that the oil selected is appropriate for the specific gearbox.

Compatibility with Materials

It is also important to consider the compatibility of the oil with the materials used in the gearbox. Some gear oils may corrode or damage specific materials, such as brass or bronze. Therefore, it is crucial to check the compatibility of the oil with the materials used in the gearbox.

Mixing Different Oil Types

Mixing different oil types can have adverse effects on the performance of the gearbox. It is recommended to avoid mixing different types of gear oils, especially if they have different base oils. However, in some cases, it may be necessary to top up the oil with a different type of gear oil. In such cases, it is essential to ensure that the oils are compatible and that the viscosity of the oils is similar.

In summary, choosing the right oil and ensuring compatibility with the gearbox materials are crucial when mixing gearbox oil. Mixing different oil types should be avoided, but if necessary, it is essential to ensure that the oils are compatible and have similar viscosity.

Troubleshooting and Problem Solving

Common Gearbox Issues

Gearboxes are critical components of many industrial machines, and they can experience a variety of issues that require troubleshooting and problem-solving. Some common gearbox issues include noise, leaks, and damage.

Noise is a common issue that can indicate a problem with the gearbox. The noise can be caused by worn bearings, gears, or other components. It is important to identify the source of the noise and address it promptly to prevent further damage to the gearbox.

Leaks are another common issue that can occur in gearboxes. Leaks can be caused by worn seals, damaged gaskets, or other issues. It is important to identify the source of the leak and address it promptly to prevent damage to the gearbox and surrounding components.

Addressing Noise and Leaks

When troubleshooting noise or leaks in a gearbox, it is important to start by identifying the source of the problem. This may require disassembling the gearbox and inspecting the components. Once the source of the problem has been identified, the appropriate repairs can be made.

Addressing noise in a gearbox may require replacing worn bearings, gears, or other components. It may also require adjusting the alignment of the gearbox or other components. Addressing leaks may require replacing worn seals, gaskets, or other components.

Repair vs Replacement

When addressing issues with a gearbox, it is important to consider whether repairs or replacement are the best option. Repairs can be a cost-effective option for addressing minor issues with a gearbox. However, if the gearbox is severely damaged or has reached the end of its service life, replacement may be the best option.

In some cases, it may be more cost-effective to replace the entire gearbox rather than attempting to repair it. This may be the case if the gearbox is severely damaged or if repairs would be too expensive.

Overall, addressing issues with a gearbox requires careful troubleshooting and problem-solving. By identifying the source of the problem and addressing it promptly, it is possible to prevent further damage to the gearbox and surrounding components.

Advanced Topics in Gearbox Oil

Synthetic Oil Advancements

Synthetic gear oil has been gaining popularity in recent years due to its superior performance and durability compared to conventional mineral-based oils. Synthetic oils are designed to withstand higher operating temperatures, reducing the risk of thermal breakdown and extending the life of the oil. They also provide better protection against wear and corrosion, resulting in longer equipment life.

Recent research has shown that synthetic gear oils can significantly reduce energy consumption and heat generation in gearboxes. This is due to their lower friction coefficients, which reduce the amount of energy required to operate the gearbox. In addition, synthetic oils have better flow properties, allowing them to circulate more easily through the gearbox and dissipate heat more effectively.

When selecting a synthetic gear oil, it is important to consider the operating temperature of the gearbox. Some synthetic oils may not be suitable for use in high-temperature applications, as they may break down or lose their viscosity at high temperatures. It is also important to consider the compatibility of the synthetic oil with any seals or gaskets in the gearbox, as some synthetic oils may cause these components to deteriorate over time.

Energy Efficiency Considerations

Energy efficiency is becoming an increasingly important consideration in gearbox design and operation. Gearboxes are responsible for transmitting power from one component to another, and any losses in the gearbox can result in reduced efficiency and increased energy consumption.

One way to improve energy efficiency in gearboxes is to use synthetic gear oil, as discussed above. Another approach is to optimize the design of the gearbox to minimize losses due to friction and other factors. This can involve using more efficient gear designs, reducing the number of gears in the gearbox, or using materials with lower friction coefficients.

In addition to improving energy efficiency, optimizing gearbox design can also help to reduce heat generation and prolong the life of the gearbox. By minimizing losses due to friction and other factors, the gearbox can operate more smoothly and with less wear and tear on its components. This can result in significant cost savings over the life of the equipment.

Frequently Asked Questions

What are the effects of using different ratios when mixing gearbox oil?

Mixing different ratios of gearbox oil can affect the performance of the transmission system. It can cause the gears to shift improperly, leading to increased wear and tear on the gears, bearings, and other components. It can also cause overheating and damage to the transmission system.

Is there a reference chart available for mixing different types of gearbox oil?

Yes, there are reference charts available for mixing different types of gearbox oil. These charts provide information on the compatibility of different types of gearbox oil and the recommended mixing ratios. It is important to consult these charts before mixing different types of gearbox oil to ensure that they are compatible.

What are the potential consequences of mixing gear oil with transmission fluid?

Mixing gear oil with transmission fluid can cause the transmission system to malfunction. The gear oil is designed to lubricate the gears and bearings, while the transmission fluid is designed to cool and lubricate the transmission system. Mixing them can compromise their performance and potentially harm the transmission system.

How can I identify the symptoms of using incorrect transmission fluid in my vehicle?

Using incorrect transmission fluid can cause the transmission system to malfunction. Symptoms of using incorrect transmission fluid include slipping gears, difficulty shifting gears, transmission overheating, and transmission failure. If you experience any of these symptoms, it is important to have your vehicle inspected by a qualified mechanic.

Are there any guidelines for recycling mixtures of oil and transmission fluid?

Yes, there are guidelines for recycling mixtures of oil and transmission fluid. It is important to properly dispose of used oil and transmission fluid to prevent environmental damage. Recycling facilities can separate the oil and transmission fluid and recycle them separately.

Is it safe to combine different viscosities of gear oil, such as 75w90 with 75w140?

It is generally not recommended to combine different viscosities of gear oil. The viscosity of the oil is designed to provide the proper lubrication and protection for the transmission system. Mixing different viscosities can compromise their performance and potentially harm the transmission system. It is important to consult the manufacturer’s recommendations before mixing different viscosities of gear oil.