Introduction

Keeping your electrical connectors in tip-top shape is important, and dielectric grease is an essential tool. But while it’s a tried-and-true solution, it’s not the only one. In some circumstances, you may need a dielectric grease alternative instead.

Here, we’ll take a look at some of the best dielectric grease alternatives that can help you protect your electrical connectors from corrosion, dust, and other elements. From silicone-based greases to white lithium grease to conductive greases and more we cover it all!

Once you’re done reading, you’ll have a full understanding of which dielectric grease alternative will best suit your needs.

What Are the Substitutes for Dielectric Grease?

Dielectric grease has a variety of uses, from protecting electrical connections to preventing corrosion, but it isn’t the only option. There are several alternatives to dielectric grease that can get the job done. Here are some dielectric grease alternatives:

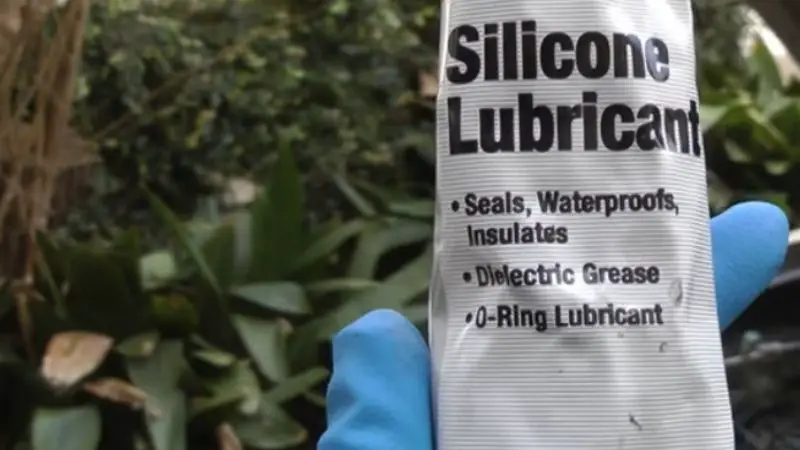

Silicone-Based Grease

It’s a versatile and powerful compound that won’t break down in the presence of water or electricity, making it a great choice for electrical applications that require an optimal level of protection.

Silicone-based grease provides superior lubrication and protection against heat, moisture, and oxidation. Its high-temperature capability and resistance to breakdown make it an ideal choice for areas susceptible to extreme temperatures or environmental changes. Plus, it won’t leave behind any residue or staining.

Check Silicone Oil Vs. Grease

White Lithium Grease

White lithium grease is a petroleum-based lubricant with additives that make it resist water and heat better than other greases. It tends to have better adherence qualities than other greases, which makes it ideal for applications where the lubricant will stay in place for a significant amount of time. In addition, white lithium grease has good oxidation stability meaning it won’t break down in high temperatures.

Since this type of grease doesn’t contain water like many other types do, it also won’t degrade electrical connections or cause corrosion on metal surfaces. As with all-dielectric grease alternatives, make sure to read the product labels and check if they are safe to use with your electric current application before purchase.

Conductive Grease

An electrical conductive grease is an excellent dielectric grease alternative, and many electricians rely on it to prevent corrosion and short circuits. Essentially, the conductive grease physically blocks moisture while allowing electricity to flow through the connection. This is quite useful in areas where moisture is present and extends the life of your electrical systems.

Specifically, conductive grease should be used when it’s necessary to prevent the build-up of static electricity due to friction between surfaces. It’s typically applied around contact points like wire nuts, terminals, and switches to prevent oxidation.

Conductive greases also come in handy when you need to reduce electrolysis between two dissimilar metals because they’re formulated with graphite or metal fibers that act as a bridge for current flow without compromising their protection from any moisture or contaminants. This makes them popular for battery connections and solar panel connections as well.

Synthetic Grease

Synthetic grease is a type of lubricant that is designed to provide superior performance in extreme temperatures, high pressures, and harsh environments. It is often used to lubricate electrical connectors and other electrical components, as it is non-conductive and provides excellent dielectric properties.

It is composed of synthetic base oils, thickeners, and additives. This base oil is typically a synthetic ester, which provides superior performance at extreme temperatures and pressures. The additives can vary and may include anti-wear agents, detergents, rust inhibitors, and extreme pressure additives. The thickeners are what give the grease its consistency and make it easier to apply.

Synthetic grease has several advantages over traditional dielectric grease. It has superior lubricity, which means it provides more protection against wear and tear on electrical components. It is also more resistant to water, which makes it a better choice for use in wet environments. Additionally, it has a much lower evaporation rate than most dielectric greases, which means it will last much longer in applications.

Vaseline

Vaseline has been used over the decades as a petroleum jelly that is both an insulator and a lubricant. It’s able to protect electrical connections against corrosion, water damage, dust, and dirt all things that can get in the way of making sure your circuit is functioning properly.

The downside of Vaseline is that it’s petroleum-based – meaning it’s flammable. So if you’re dealing with an environment with high temperatures or sparks, then Vaseline is not the right choice for you. But it’s perfect for low-voltage electrical circuits and devices where heat isn’t a major concern.

How to Use Dielectric Grease?

Dielectric grease is a versatile and helpful product in many maintenance tasks. It’s often used in electrical connections, to help protect and keep them conductive. It keeps water, dust, and other foreign particles out of the connection, preventing rust or corrosion that can lead to failing connections or short circuits.

Here’s how to use it: First, start by cleaning any dust and dirt from the connection and apply it directly to the male connector. Dielectric grease is also a great way to help seal out moisture and prolong the life of rubber components such as weather-stripping on cars or around door frames. To do this, simply run a thin film on the parts before installation.

Besides being used on electrical connections and rubber components, dielectric grease can also be used on hinges and locks to help prevent corrosion. It’s also helpful on battery terminals after cleaning them to improve the conductivity of electricity impacting performance and the life of your battery.

No matter what job it’s used for, dielectric grease will provide protection against corrosion while helping maintain excellent connection quality for all your electrical needs.

FAQs

Q. Is battery terminal grease the same as dielectric grease?

No, battery terminal grease and dielectric grease are not the same. Battery terminal grease is an insulating compound that is used to protect battery terminals from corrosion and other damage, while dielectric grease is used to protect electrical connections from moisture, dust, and other contaminants.

Q. Can I use WD-40 instead of dielectric grease?

WD-40 is designed to be a good sealer. When it dries, it leaves a thin film on your electrical equipment that does not interfere with electrical connections. Therefore, using it on electrical devices is safe without worrying about damaging them.

Q. Can vaseline be used as dielectric grease?

Yes, vaseline can be used as a dielectric grease. It acts as an insulator and sealant that prevents corrosion and maintains electrical connections. It also helps to keep dirt, dust, and other contaminants from entering electrical connections.

Q. Can I use silicone grease in place of dielectric grease?

No, you should not use silicone grease in place of dielectric grease. Silicone grease is not an electrical insulator and can cause electrical shorts in electrical connections. Dielectric grease is designed to be an electrical insulator that protects electrical connections from moisture and oxidation.

Q. What oils are dielectric?

Dielectric oils are non-conductive oils that are used to insulate electrical components and reduce the risk of electrical discharge. Common dielectric oils include mineral, silicone, polybutene, and polyalphaolefin. These oils are often used in transformers, capacitors, and other electrical components.

Conclusion

Dielectric grease is an excellent choice for keeping electrical components waterproof and well-insulated. However, depending on the nature of the application, it may be necessary to look for an alternative such as silicone-based grease, white lithium grease, conductive grease, synthetic grease, vaseline, or bulb grease. Each of these has different properties and should be used for specific purposes.