When you switch to Amsoil, your compressor will run more efficiently because of the oil’s lower friction properties. Thus, it will prevent viscosity from oxidation over time during use.

Amsoil compressor oil SAE 20 also decreases carbon, varnish, and acid formation over the life cycle of the oil. Additionally, it prevents water pollution and reduces the possibility of hot spots forming inside your compressor.

Besides this, it comes to provide high performance and protection in air compressors. Also, they come with a proprietary additive system that exceeds the necessities of all key compressor manufacturers. They are great for Sullair, Atlas Copco, Ingersoll Rand, and many other compressor brands.

Most importantly, Amsoil offers a complete line of synthetic compressor oils to meet the needs of all air compressors. To know more about that, please stay with us.

What Is Amsoil Air Compressor Oil?

Amsoil air compressor oil is a synthetic oil that lasts up to 8,000 hours. This oil is ester, PAO, and petroleum-based oils. Notably, this makes it easy to replace when it’s time to service your compressor and change the oil.

Don’t worry about any chemical reactions causing damage to your compressor. Hence, if you’re using a glycol- or silicone-based oil, drain this oil fully before switching to Amsoil synthetic. It’s because they are not compatible with mixing purposes.

AMSOIL 100% synthetic compressor oils are competitively priced. Typically, they offer outstanding hot or cold performance and excellent wear control. Even they offer maximum friction reduction for energy savings.

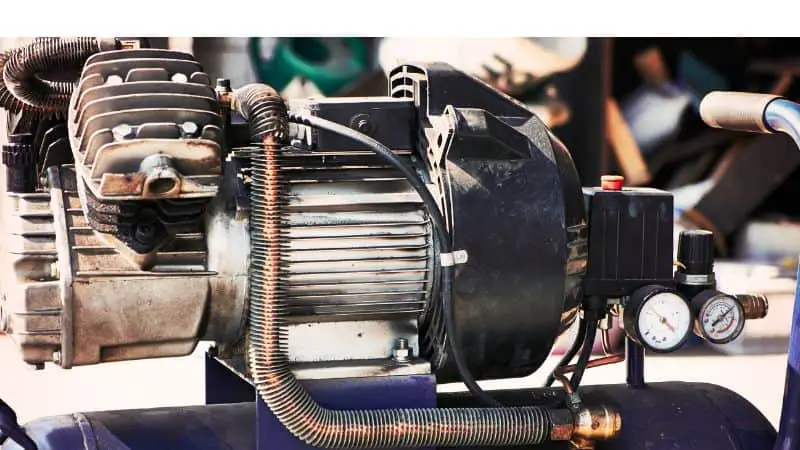

If you use a large compressor like a single or multiple-stage rotary vane, or reciprocating type, you should cool it.

Synthetic Compressor Oil ISO 46 SAE 20

Synthetic compressor oil ISO 46 SAE 20 is a premium compressor lubricant based on new technology. Moreover, it gives you a long life service.

Yet, it includes the highest quality and thermally stable PAO synthetics. And it was protected by additives of premium non-detergent for higher protection at high temperatures. In particular, it lasts up to 8,000 hours, effectively, decreasing maintenance and waste oil disposal costs.

Advantages Of Synthetic Compressor Oil ISO 46 SAE 20:

There are many advantages of synthetic compressor oil ISO 46 SAE 20. 20-weight air compressor oil advantages are:

Improves Compressor Efficiency

AMSOIL PC Series oils have low friction properties, preventing viscosity increase from oxidation. Yet, it can help develop operating efficiency.

Controls Foam and Decreases Wear

Synthetic oils have anti-foam additives and unlike other compressor oils, are anti-wear fortified. Great foam control decreases oxidation, heat, and wear. The High contact areas are protected against wear for extended compressor life and low maintenance costs.

Prevents Water Pollution

Water from condensation makes compressors and causes unwanted oil/water emulsions that can lead to rust and corrosion. In addition, these oils are hydrolytically stable.

So, it resists acid formation, separates easily from the water, and is strong anti-rust. Water can easily drain for simplified disposal and increased oil life.

Security Facilities

SAE 20 compressor oils are an ashless, high-flash-point formulation with a very low carbon build-up tendency.

That’s why it minimizes the occurrence of ignition-promoting “hot spots.” Although PC series oil may provide developed fire safety, it is not considered non-flammable.

Application:

Synthetic compressor oils are recommended for use in single and multistage vanes, rotary screw, centrifugal and more. Also, you can use these oils in other applications like bearings, gears, blowers, and pumps.

Synthetic Compressor Oil 46:

Synthetic compressor oil 46 is a fully synthetic, high-quality lubricant based on improved digester technology. You can find them in five ISO grades to cover a broad range of components and operational conditions.

All grades provided huge advantages compared to mineral oils in high-temperature applications. Nevertheless, it provides long service life and necessary minimal deposits.

They have excellent oxidation resistance giving up to 10 times the mineral oil service life. The synthetic compressor oil ISO 46 provides an increased service life in rotary screw compressors (up to 8,000 hours).

Even it decreases deposits in single and multistage reciprocating compressors. They show a significant improvement in performance over mineral oils in pumps, gear reducers, mist systems, and other applications.

Read About: Rotary Screw Compressor Oil

FAQ (Frequently Asked Questions):

Q. What weight oil should I use in my air compressor?

Most air compressors use 20 or 30-weight non-detergent oil. 20-weight is generally best for cold environments and 30-weight for warm environments. Therefore, you should always use the recommended oil for your air compressor.

Q. Can I use 10W30 in my air compressor?

No, you can’t. The air compressor manufacturers and air compressor experts recommended using air compressor oil without detergent. Especially, 10W30 contains detergent, so don’t use this oil in your air compressor. In particular, its viscosity and weight cant meet the manufacturer’s specifications.

Q. Can I use 30-weight oil in my compressor?

Although 30-weight oil is more effective in coating parts, it may become too thick to use if the temperature is too low. A 20-weight oil will work much better in colder environments to keep the compressor up and running when needed.

Q. Is SAE 30 good for air compressors?

You can use synthetic or mineral oil in your air compressor and have it work perfectly. Therefore, you should avoid using detergent additives oils, it’s common in motor oil. Ergo, you need to use oil with non-detergent.

In terms of viscosity, you can use SAE 30 or SAE 20 air compressor oil for your air compressor. In general, your air compressor manufacturer will tell you what oil to use with every compressor model.

Final Word

On the other hand, you should use specific types of air compressor oil for an air compressor. But many people make the common mistake that all oils are the same. That’s why you should use proper oil for your air compressor.

Generally, Amsoil compressor oil SAE 20 can last five to ten times longer than comparable petroleum oils. This means longer equipment life through reduced oil costs and better performance. Ultimately, the Amsoil compressor oil is designed with proprietary tech and the best additives.

Overall, its outstanding benefits are water resistance and heat resistance. However, the Amsoil compressor oil will be the best oil for your air compressor. So, use this incredible oil and get the best performance from your compressor.

Read About: Pro-Tec Compressor Oil