Refrigerant is essential for its cooling properties; refrigeration oil is crucial for the proper functioning of compressors. Oils in refrigerator compressors decrease friction, prevent wear, and work as a seal between low and high pressure. But choosing the best refrigerator compressor oil is critical.

Although refrigerator oil’s primary function is lubrication, it should be able to tolerate high-temperature differences. Besides this, it is compatible with refrigerants. By understanding how lubricant interacts with the refrigerant, you can ensure that your compressors run as efficiently as possible. However, to know more about this topic, please keep reading.

What Is Refrigerator Compressor Oil?

Refrigeration oil acts as a hydraulic control, working fluid, and lubrication oil in refrigeration compressors.

Mainly, refrigeration lubrication compressors occupy a specific position in lubrication technology. The expected longevity of the refrigeration compressor is closely linked to the high quality needed for refrigeration oil.

Therefore, with other substances, the interaction comes into contact with the refrigeration oil. Specifically, this interaction’s low and high temperatures make very particular demands for this oil.

Basically, the compressor oil‘s main job is to lubricate the rotors and pistons. Furthermore, its other job is to lubricate the valves and seal the slip rings. On the other hand, this oil must carry heat away from hot compressor elements. Yet, it helps to seal the compression valves and chamber.

Furthermore, refrigeration oil must carry heat away from hot compressor components and help seal the compression chamber and valves.

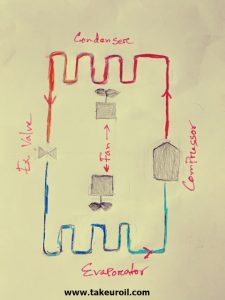

How Does a Refrigeration System Work?

The cycle of most normal refrigeration cycles is accomplished by evaporating and circulating in a closed system. Evaporation happens at low pressure and low temperature, while condensation happens at high pressure and high temperature. It makes it possible to shift heat from an area of low temperature to a place of high temperature.

- The hot narrow vapor enters the condenser, condenses, and cools into liquid, producing heat.

- In the vapor phase, the refrigerant enters the compressor and compresses to high pressure, resulting in an extreme temperature.

- The mixture of cold enters the evaporator. Therefore, the cold liquid portion refrigerant mixture evaporates.

- The refrigerant condensed fluid flows through a stretch valve where the pressure decreases. Similarly, the pressure drop causes a portion liquid refrigerant portion to evaporate. In addition, it reduces the liquid temperature and mixture of vapor refrigerants.

How to Select the Appropriate Refrigerant?

The essential refrigerant properties are:

- the heat required to vaporize the liquid

- densities in the liquid and vapor phase

- boiling point

The correct refrigerant selection is primarily based on the suitability of its temperature relationship for the specific application range.

Refrigerant temperatures in evaporators and condensers are cold and hot section temperatures. It determines the high pressure in the condenser and evaporator.

Requirements For Refrigeration Oils

Thermal Stability

Refrigeration oils have to work correctly over a broad range of temperatures. The final compression temperature in refrigeration compressors can reach a maximum temperature of up to 180ºC. Furthermore, refrigeration oil must therefore be thermally stable.

The lighter rims enter the compressor system as vapors if the oil has a volatile oil fraction. Moreover, they condense and decrease the heat transfer efficiency and enhance the oil’s viscosity.

Chemical Stability

To avoid reaction with refrigerant, the oil should be chemically stable.

Refrigerant/Oil Solubility

Refrigerant mixtures of oil can be partially soluble or insoluble. Complete solubility benefits lubrication but can cause significant viscosity loss in the compressor, which increases.

Refrigerant Oil Types:

Accordingly, refrigerant oil is circulated with refrigerators (like R-22, R-32, R-410a, R134a, etc.). Not all oil is compatible with all refrigerators. Namely, the type of oil selected must be mixed with the refrigerant.

Miscibility means, in the line set, the oil and refrigerant can be safely mixed and circulated in the air compressor. Nevertheless, there are two main types of refrigerant oils:

The two types of refrigerant oils are:

- Mineral Oils, and

- Synthetic Oils

- Mineral Oils:

Mineral oil was first produced from the refining process of petroleum. Likewise, these oils are produced when crude oil is distilled to produce gasoline.

Regardless, mineral oils are suitable for older-generation refrigerants, including CFCs and HCFCs. Subsequently, you can use this oil with older refrigerants like CFCs and HCFCs.

- Synthetic Oils

The mineral was excellent for earlier refrigerator generation systems, like CFCs and HCFCs. After passing out HCFCs and CFCs, they had to produce new oils for new refrigerators. And the new oil name is synthetic oils.

Synthetic oils are made from processed petroleum to have specific properties to work with the new refrigerants. Synthetic oil is required when making retrofits because mineral oil cannot misplace with modern refrigerants. This means that the mineral oils do not mix well with the new refrigerant, which prevents the refrigerants from doing their job.

Consequently, you need synthetic oils to make retrofits. The reason is that mineral oils aren’t miscible with modern refrigerants. That means mineral oils don’t blend with modern refrigerants. Besides, they hinder refrigerants from doing their job. More synthetic oils are available that can lubricate your refrigerant compressor system.

There are:

- Alkylbenzene (AB)

- Polyester (POE)

- Polyalkylene Glycol – (PAG)

- Polyvinyl Ether (PVE)

- Polyalphaolefin (PAO)

Alkylbenzene (AB):

You can use this Alkylbenzene (AB) synthetic oil in refrigerant systems with CFC or HCFC refrigerants. Notably, these oils contain good chemical and thermal stability. With refrigerants, visibility is high. Usually, they are entirely soluble in PAO and mineral oil. And this solubility makes it possible to produce mixtures to develop lubricant properties.

So, for mixtures containing HCFCs, you need to use alkyl benzene (AB) to service the compressor system.

Polyoester (POE):

Polyolester (POE) refrigerant oil is one of the most common types of synthetic oil used with HFC refrigerants oil R134a. Thus these oils contain HFO and HFC refrigerants. Generally, it’s indicated as ester oils. You must use this oil to retrofit with HFC or HFC mixtures.

Note that the meaning of retrofitting is changing a system to utilize a modern refrigerant. Hence, you cannot mix POE compressor oil with any other oils. When supplying tools using ester-based oils, it would be best to keep it in mind.

Polyalkylene Glycols (PAG):

Undoubtedly, you can use this oil in refrigerant because it will attract water. Most importantly, this oil contains thermal stability and a high viscosity index. PAG is hygroscopic, soluble in ammonia, and suitable for PAG oil r134a.

Accordingly, you also can use this Polyalkylene Glycol (PAG) synthetic oil in vehicle air conditioning systems.

Polyvinyl Ether (PVE):

And lastly, polyvinyl ether (PVE) is a synthetic oil alternative to POE oils.

Polyalphaolefin (PAO):

These refrigerator compressor oils also come with excellent thermal and chemical stability. PAO has great viscosity-temperature properties.

It’s essential to have low miscibility in refrigerants. It’s needed to use PAOs in refrigeration applications where miscibility isn’t a problematic matter. PAO can shrink seals, and you can solve it by mixing PAO with AB.

FAQs( Frequently Asked Questions):

Q. How to change the oil in a refrigeration compressor?

- Step 1.

First, determine if the system uses a standard compressor with a different engine and suitable valves.

- Step 2.

A sealed unit requires you to reclaim and clean the system and check for leaks. Then it would help if you pulled a vacuum before returning the oil and refrigerant to the system. The oil and refrigerant charge will be on the unit nameplate. And it would help if you charged on the discharge side of the unit.

- Step 3.

You must also document the amount of gas reclaimed, and the amount of gas returned to the system.

Q. How to remove oil from the refrigeration system?

Getting excess oil in the refrigerator system is undoubtedly frustrating but solvable! Removing oil from your refrigerator can require a little more know-how. So, if you think you can do it, then you can follow the below steps:

- First, you should flush your whole system with compressed air and solvent.

- Vacuum up extra oil with a wet-dry vac

- Now you should flush your refrigerator system with rubbing alcohol.

- Add the oil again to this system.

Q. How much oil goes in a refrigerator compressor?

You need to put 10 ounces of compressor oil in your refrigerator compressor. And, when you deliver the compressor to the car assembly plant, full oil is present in the compressor.

Q. How much PAG oil do I add to a new compressor?

Drain your new compressor, then add the same amount of PAG oil that had come out from your old compressor. For example,

For example, if the broken compressor you removed had 3 ounces, you should put your compressor with 3 ounces.

Q. Can a fridge compressor run without oil?

No, because another possible cause of early compressor death is oil loss. Like a motor car, a refrigeration compressor requires adequate oil to run correctly. You should put the oil in to acquire its design efficiency and have a long life.

Final Word

In summary, selecting the proper refrigerator compressor oil depends on the compressor specifications and the refrigerant. Refrigerant oil should be thermally and chemically stable. Remember, don’t use that oil that can react with your refrigerant.

Overall, it’s also essential to how the oil interacts with the refrigerant and how the mixture works. Ultimately, lubricant problems can happen if lubricant viscosity becomes low because of oil absence.