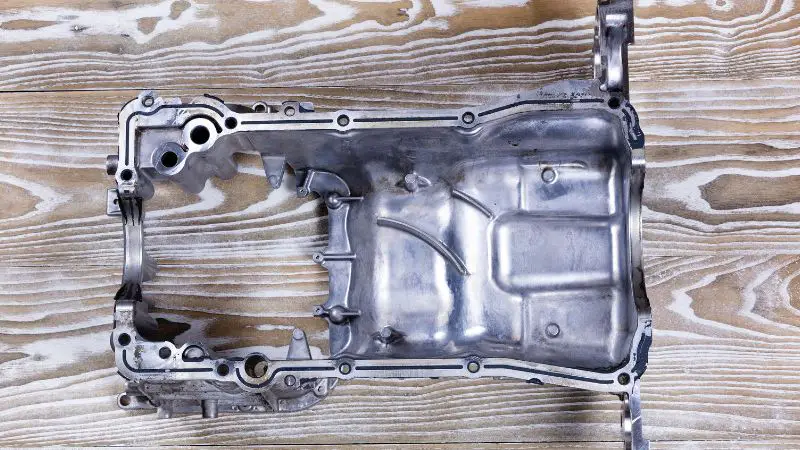

LS engines are the most famous in the automotive industry, providing high performance, versatility, and durability. Also, this engine’s most crucial component is an oil pan, which maintains the engine’s lubrication systems.

However, every experienced driver must know about the LS oil pan torque sequence. But if you are new to it, we will help you. Learning about the oil pan torque sequence becomes crucial when you want to make some changes to your engine. Let’s know about LS oil pan torque sequences in detail.

What Is The Torque Setting For an Oil Pan?

Have you noticed the oil is leaking from the pan and not going to the bottom, or is it being pumped from somewhere else? There must be a reason the bolts are loose. If your sump is leaking oil, the bolts can only be finger-tight.

Put a wrench on them and see how much slack you can take. If it’s more than a quarter of a turn, whoever replaced the pan didn’t tighten them properly. Basically, the sump is a non-load bearing or stressed item, so it probably doesn’t have a specific torque setting. It must be tight enough to compress the gasket to prevent hot oil from escaping.

You need to tighten all the bolts by hand and clean everything you can reach. And then take the car for a long run. After doing it, Jack it up and see exactly where the oil comes from. Remember to plug the sump.

Oil Pan Torque Specs:

Your LS engine torque specs will depend on the model and vehicle manufacturer. The standard LS engine is rated at 475 Nm with 345 Hp.

| Engine Parts | Torque |

| Camshaft Retainer Bolts | 18lb-ft |

| Camshaft Sensor Bolts | 18 lb-ft |

| Camshaft Sprocket Bolts | 18 lb ft |

| Connecting Rod Bolts- First design(first pass) | 15 lb-ft |

| Connecting Rod Bolts- First design(second pass) | 15 lb ft |

| Connecting Rod Bolts- First design(final pass) | 60° |

| Connecting Rod Bolts- Second design(first pass) | 15 lb-ft |

| Connecting Rod Bolts- Second design(final pass) | 75° lb-ft |

| Crankshaft Balancer Bolt – Installation Pass | 240° lb-ft |

| Crankshaft Balancer Bolt – First Pass | 37 lb-ft |

| Crankshaft Balancer Bolt – Final Pass | 140° |

| Crankshaft Bearing Cap Bolts – (Inner Bolts-First Pass In Sequence) | 15 lb ft |

| Crankshaft Bearing Cap Bolts – (Inner Bolts-Final Pass In Sequence) | 80° |

| Crankshaft Bearing cap side bolts | 18 lb-ft |

| Crankshaft bearing cap studs (outer studs-first pass in sequence) | 15 lb-ft |

| Crankshaft bearing cap studs (outer studs-final pass in sequence) | 53° |

| Crankshaft Position sensor bolts | 18 lb-ft |

| Cylinder head bolts (first pass all M11 bolts in sequence) | 22 lb-ft |

| Cylinder head bolts (final pass all M11 bolts in sequence) | 90° |

LS Oil Pan Torque Sequence:

You should follow a specific order when tightening the oil pan bolts to avoid oil pans distorting. It’s the torque sequence and is very important for the LS engine series. Typically, these engines use a star pattern or crisscross to tighten the oil pan bolts.

Equipment Preparation:

To get started, prepare the essential tools. It would help if you had a torque wrench to tighten the oil pan bolts because it can provide proper torque. Generally, a 3/8-inch drive torque wrench can deliver the best.

Using a torque wrench to apply a proper force to the bolt or nut is very important. It’s to make sure that you can tighten the bolts perfectly. So you can avoid damage and build a proper seal.

Primary Position:

With these tools, you can begin to work. Be sure to align the pan with the engine block properly. Furthermore, you need to align the holes in the pan with the block. To make proper fit and seal alignment, it is necessary.

After installing the oil pan, insert all bolts manually and appropriately threaded to prevent cross-threading. Cross-threading can damage engine blocks, bolt threads, and threaded holes.

First Pass: Primary Tightening

For the first pass, you should tighten all the bolts slightly so that the threads engage and secure the pan. Nevertheless, don’t tighten them finally at this point. It’s because the goal is to produce an initial seal and keep the pan firmly.

To keep the pan from warping, start with the center bolt and work outward in a star pattern. This star pattern can circulate pressure equally across the pan and make a uniform seal to begin with.

Second Pass: Tighten to Half Torque

To complete the second pass, use a torque wrench to tighten each bolt to half. For most LS engines, it means tightening them to about nine pounds (ft. lbs.) or 12 Newton meters (Nm).

To ensure a secure seal, tighten the oil pan in a star pattern and gradually boost the tension. Because of gradual hardening, the pan and gasket can adjust to pressure and prevent distortion, resulting in a good seal.

Final Pass: Full Torque Tightening

To complete the procedure, you should tighten every LS engine bolt to the suggested torque specification, like 18 ft-lb. Again, using a star pattern, ensure you can securely tighten each bolt to maintain a long-lasting seal.

5.3 LS Oil Pan Torque Sequence

The 5.3 LS engine oil pan sequence will vary significantly by bolt type. Each of these bolt types demands different methods for applying torque. However, you can perform 5.3 oil pan torque sequences with the following instructions:

- Hand-tighten the bolts after guiding them properly, and begin by torquing the opposite center bolts.

- Begin on one side, torque the bolts facing each other, and move on to the next.

- The sequence must be followed for all bolts, and then you must retighten it.

The front machine covers are 18 ft lbs, and the back bolts are 106 lbs. Other tools need to be torqued down to 37 foot-pounds. The 5.3 oil pan bolt torque includes the bell housing, gearbox cover, and converter.

6.0 LS Oil Pan Torque Sequence

For this, you must first ensure you have a 6.0 LS engine. Additionally, if you need to replace the oil pan crankcase, follow these steps:

- Park your car on dirt pavement, on flat ground.

- Now, you need to open the drain plug and unbolt the crankcase.

- Then torque the bolts by hand until you get them tight.

- With a criss-cross pattern, torque the 11mm bolts to 13Nm.

FAQ (Frequently Asked Question):

Q. What is the Torque Sequence?

Basically, torque sequencing refers to the application of rotational force to an object. To be more specific, torque has a significant effect on any bolt. Primarily, torque must be applied if you need to make tension on a bolt.

Eventually, the process transforms a bolt into a spring-type element, significantly creating two different aspects. But in this method, you need to apply the torque correctly. To complete the torque sequencing strategy, you should measure adequately. Doing too much will break the bolt.

Q. How important is the torque sequence?

Performing the torque sequence means tightening the crankcase screws on your engine below. Notably, if you don’t fight it properly, it can cause oil leakage. If it is too tight, it directly stresses the engine threads, sometimes damaging all the bolt threads.

Automobile manufacturers advise that torque sequences are necessary to decrease preload. If you can run the torque sequence, it ensures that your bolts are tightened perfectly. So, torque sequences are essential to keep your engines in good condition.

Q. What do I torque my transmission pan to?

Yes. A transmission pan is a metal container found under the transmission. Typically, it holds the transmission oil and acts as a reservoir. The pan is secured to the transmission housing using a series of screws. Torque specifications for these clasps are essential to ensure proper sealing and prevent leakage.

Yet, you must follow the proper torque specifications to torque your transmission pan. The reason is that, in your transmission systems, insufficient torque can cause loose bolts, liquid leakage, and possible damage. Subsequently, excessive torque can cause over-tightening, resulting in distortion of the transmission pan.

Final Word

On the other hand, following the correct LS oil pan torque sequence is critical to ensure proper operation and long life. Torquing the bolts of an oil pan should be hassle-free if you have the right specs and know the procedure. Before torquing, take torque specs from your vehicle model and follow the correct sequence. Here, we are trying to discuss how to torque sequence. We hope you know the procedure and can apply it easily to your vehicle.