Viscosity index improvers are additives that improve the viscosity of the fluid throughout its necessary temperature range. These additives are referring to polymeric molecules which are very sensitive to temperature.

What Is the Viscosity Index?

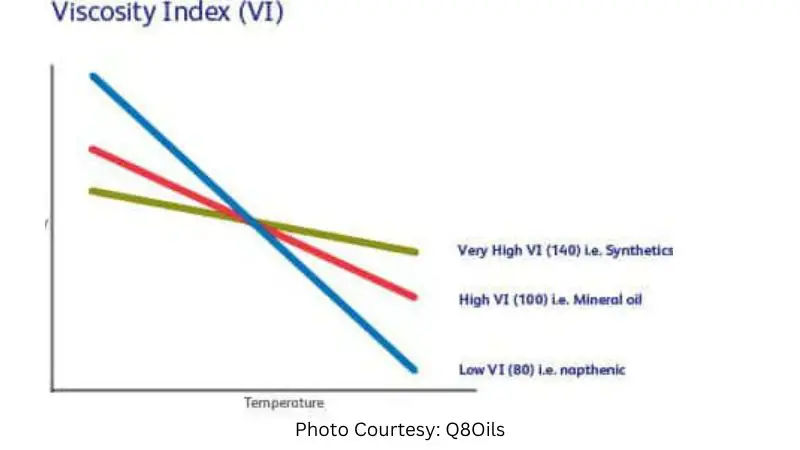

The viscosity index is a measure of the change in viscosity of a liquid concerning temperature changes. The higher the viscosity index, the smaller the comparative change in thickness with temperature.

As the temperature enhances, these molecules expand. As the molecules expand, the internal friction of the fluid will increase, as a result of the fluid flow slower. However, this article will give you a better understanding of viscosity index improvers. So, please, carry on.

Formula For The Viscosity Index:

Viscosity Index Calculator

Y = dynamic viscosity at 100° C of the petroleum product which VI requires to be calculated, mm2 /s. H = At viscosity index 49°c, kinematic viscosity 100 of oil comes with similar dynamic viscosity as the oil at 100 °C. And its viscosity index is calculated at mm2 /s.

Viscosity index improved examples include multipurpose tractor transmission fluids, automatic transmission fluids, power steering fluids, industrial gear oils, and more.

Viscosity Index Improvers

Generally, a viscosity index improver is a tough polymer additive that extends at higher temperatures to thicken the lubricant. Also, it can ensure a more stable and compatible viscosity. It ensures that this lubricant protects the tools at both high and low temperatures.

Correspondingly, it also allows for multigrade oil formulation which removes the requirement for seasonal oil changes. Moreover, they are extensively based on their molecular structure and chemistry. That’s why, unfortunately, no simple calculation is possible.

Any additive supplier can provide a mixture chart with the right information which you are searching for. This chart should identify the blend viscosity and viscosity index based on a given treatment rate.

What Is Used For Viscosity Index Improvers?

Materials commonly used to improve viscosity index include polymethacrylates (PMA), radial polyisoprene, polyisobutylene (PIB), and olefin copolymers (OCP). Since they come in different types but every material has its response curve.

Furthermore, they are normally used in gear oils, multigrade motor oils, power steering fluids, greases, automatic transmission fluids, and hydraulic fluids. Besides, at low temperatures, they allow your liquid to flow more fairly so that it reaches the bearings quickly.

At high temperatures, fluids will have a high viscosity. Even so, they offer the necessary film thickness to save the moving parts and bearings within your tools. A major problem with viscosity index-improving additives is that they are very sensitive to mechanical shearing.

For example, imagine one piece of spaghetti moving across an engine or oil in a gearbox. There are places in the engine that have extremely tight clearances and will work like scissors cutting the spaghetti noodle. This extensively decreases the ability of molecules to add viscosity to the liquid over time.

What Does Viscosity Index Improver Do?

Simply put, a VI improver helps a lubricant become too thin at high temperatures. Think of a full honey glass – the liquid becomes viscous and thick at low temperatures. Nonetheless, after exposure to heat, honey flows much more easily and has less viscosity.

If the lubricant viscosity decreases and becomes too thin, the protective features are reduced leading to equipment wear and damage. High molecular weight polymers have the good thickening ability but are more sensitive to mechanical shear.

On the contrary, low molecular weight polymers have large shear stability but must use higher cure rates. When selecting the correct viscosity index improver, it’s necessary to think about the requirements of the finished liquid. A few polymers are prone to oxidative corrosion and thermal at high temperatures, so you have to choose a higher thermal and oxidative stability polymer.

Viscosity Index Improver formula

To improve the viscosity index of lubricating oil, an investigation was directed from a vacuum distillation lube oil plant. In this experiment, two types of solvents were used to extract unwanted materials.

And it increased the crude lubricating oil fraction’s viscosity index. The 1st solvent was furfural that’s not used in Iraqi refineries. The 2nd one was NMP which was used in this work for the first time.

The variables influencing extraction studies were expulsion temperature range from 70 to 110° C for furfural. Its solvent ratio ranges from 0.5:1 to 2:1 (wt/wt). On the contrary, NMP extraction starts from 1:1 to 5:1 (wt/wt).

This investigation results show that this oil viscosity index friction enhances with expanding expulsion temperature. Solvent-to-oil ratio reaches 83 for NMP extraction at an extraction temperature of 110° C and a solvent-to-oil ratio of 2:1. While the viscosity index of furfural at the same time reaches 80 for extraction.

A higher viscosity index of the oil fraction is obtained using NMP rather than furfural under similar operating variables. Moreover, the results showed that the viscosity, percentage yield, and refractive index of the raffinate were reduced with increasing extraction temperature or solvent-to-oil ratio for NMP and NMP extraction.

How to Improve The Viscosity Index Of Lubricating Oil

Conventionally, lube oil stocks adopted by vacuum distillation or vacuum residue distillation will be improved by solvent expulsion to expand VI. The viscosity index improves polymers that are added to base lubricating oils against temperature levels during internal burning engine operation.

In this work, a particular viscosity index improves by mixing DQC with polyoxyethylene (p 20) in the presence of myostatin as a solvent. The prepared VI was added to the base lubricating oil grade SN-500 made from Al-Dorah Refinery. And it came at different weight ratios, adding 7.8% to SN-500 base oil.

The effect on VI other properties is improved without 14 degrees of oil. As we know, VI is a measure of viscosity change with temperature change. Similarly, it is necessary to describe the viscosity-temperature lubricating oils’ behavior. If the viscosity index is low the viscosity changes more with temperature.

The viscosity index has no units calculated using oil viscosity at 40˚C and 100˚C. Most applications need oils to perform satisfactorily over a broad range of temperatures.

In automotive engines, low-viscosity oil needs the ability of the oil pump to push the oil through the engine.

Viscosity Index Improver Manufactures

Engines used in the automotive and industrial sectors don’t run at a certain temperature everywhere. Therefore, the use of lubricants helps the engine to work perfectly at all temperatures.

Additionally, VI improvers are additives utilized to develop engine performance by improving the performance of lubricants at low and high temperatures. Moreover, they maintain the lubricant viscosity at low and high-temperature conditions composed of polymeric molecules.

Based on type, you can segment the global viscosity index improver market into olefin copolymer, polymethacrylate, polyisobutylene, and others. In terms of capacity and volume, Polymethacrylate dominates the market by more than half.

On an end-user basis, you can segment the global viscosity index improver market into off-road vehicles, automotive, and others. The main players in the global VII market are Total oil company, The Lubrizol Corporation, Chevron Oronite Company LLC, etc.

FAQs ( Frequently Asked Questions):

Q. Why is the viscosity index important?

Adequately, the viscosity index allows an excellent comparison of different oils’ viscosity behavior based on temperature. Usually, it is important to ensure excellent possible lubrication for tools, as temperature happens during operation.

Q. What is the viscosity index used for?

The viscosity index is a despotic, unitless measure of the change in viscosity of fluid for temperature changes. To characterize the lubricating oil’s viscosity-temperature behavior used this viscosity index.

Q. What are viscosity modifiers?

Viscosity modifiers come to decrease the change in lubricant viscosity with temperature changes. Since it’s one of the main components of motor oil, the selection of viscosity modifiers is necessary for making quality lubricant.

Q. What is OCP Polymer Viscosity Index Improver

OCP viscosity index improver is an olefinic copolymer oil condense recommended primarily as a Viscosity Index Improver. Even so, this is very essential for crankiness lubricants where you want good shear stability.

As an OCP polymer ethylene-propylene copolymer to improve the viscosity index, this is a broadly used lubricant additive material. So, it can be mixed with other types of lubricant additives to form a variety of additive packages. Particularly, this olefin copolymer is formulated for use as a viscosity thickener for olefin copolymer engine oils. It provides amazing shear stability and lower temperature properties to heavy-duty and passenger car motor oils.

Read More About Viscosity Modifiers

Final Word

The lubricant viscosity is affected by changes in its temperature. An oil’s viscosity index offers an intimation of its potential for a broad temperature range of applications. In particular, viscosity index improvers are very important in every lubricant field, although motor oils represent their highest application.

Besides this, they play an important role in formulating multigrade oils. However, this is all about VI improvers, so from here you can get maximum information about this topic. Ergo, thanks for reading this article with patience.