In hydraulic oil, viscosity is very crucial. Viscosity is the critical property of hydraulic oil that affects the hydraulic system’s performance. The oil’s viscosity determines which oil will be selected for which application. But how to check hydraulic oil viscosity?

Viscosity needs to be suitable for both the job and the condition it’s in. Different machines need different viscosities of hydraulic oil. Generally, the higher the working pressure, the higher the viscosity required. Older machines will usually need a higher density. However, let’s talk about hydraulic oil viscosity and check the method of calculating the viscosity of hydraulic oil.

Related: Power Steering Fluid vs Hydraulic Fluid: Any Difference?

What Is The Viscosity Of Hydraulic Oil?

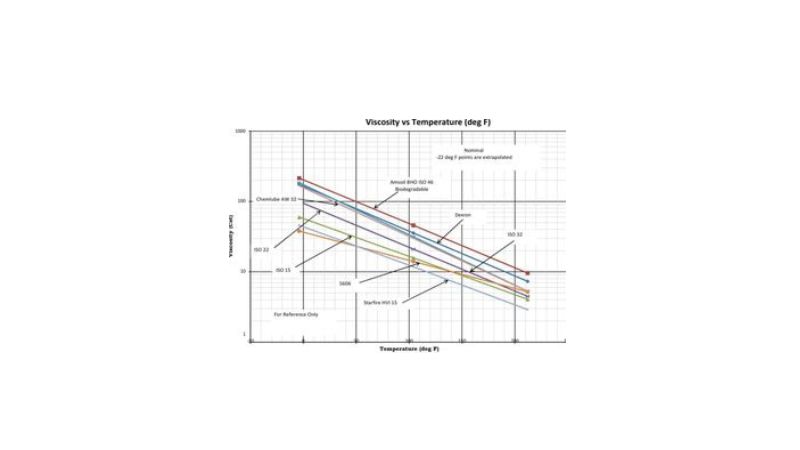

The hydraulic oil viscosity is affected by temperature. Not just because of the ambient temperature, the machine-generated temperature.

The viscosity of the hydraulic oil determines the strength and thickness of the fluid film selected in the machine. A fluid with a low density will flow faster, and one with higher viscosity can pour more slowly.

If the viscosity is too low, the hydraulic fluid may leak and not provide enough cushion to the working parts. This results in energy loss and high levels of corrosion in the system. Hydraulic oil viscosity is the most considered property that decreases the machine’s wear and improves accuracy.

Usually, the viscosity of hydraulic oil can be classified as dynamic viscosity or kinematic viscosity. An oil analysis laboratory uses an onsite viscometer and kinematic viscosity to measure dynamic viscosity.

Hydraulic pump and motor manufacturers were surveyed about fluid viscosity. Most equipment performs satisfactorily with a viscosity range of 13 to 860 CST.

How To Check Hydraulic Oil Of Viscosity?

We know hydraulic oil viscosity is essential for all hydraulic systems. You should know how to ensure your hydraulic oil remains at the proper viscosity.

You need to monitor hydraulic oil viscosity to ensure its proper level. Like all oils, this oil also loses viscosity over time. Viscometer is an oil viscosity-measuring instrument. However, let’s discuss how to check the viscosity of hydraulic oil step by step:

- First, support the viscometer vertically, loosen the bleed valve, then pull the sliding plug.

- Make sure the viscometer tube is clean and clear. Then put the metal ball into the chamber.

- Fill the tube with the oil sample above the V-plate.

- Push in slowly and rotate the plug with the valve open until all the air is out. Do not use excessive force to fit the bleed valve loosely, and keep the viscometer in a straight position. And leave for 5 minutes to stand it.

- Tighten the bleed valve and remove excess oil from the plug.

- Put the viscometer again on its base and engage the power cable.

- Use the reset key to start your operation.

- Use the arrow keys to toggle the display and select the required temperature with the return key.

- As the viscometer heats the oil, the temperature flashes.

- The degree (°) mark is lit until the oil temperature stabilizes.

- If requested, you tilt the viscometer. After stabilizing the hydraulic oil temperature, the display will show you as selected viscosity as 40° or 50°.

- Wait for tilting before taking resort readings. To toggle the display of CST from 40° or 50° to 100°c, you can use arrow keys.

- Once the test is complete, turn off the power supply and separate the yellow lead from the viscometer.

- Carefully drain the oil from the tube. Use the supplied drive to catch the metal ball tip oil in a container.

How To Test Hydraulic Oil Viscosity At Home?

The procedure is complex and probably dangerous. It should only be undertaken with extreme care, proper equipment, and safety measures. Let’s go to the test at home:

- Fill a pot with water and boil at 100 degrees. The water should be deep enough to submerge an object but not so complete that it spills over. Maintain temperature throughout the test.

- Immerse an open-ended U-shaped glass tube in water, so the curve is immersed, but the edges are open to the air. Seal one end of the tube.

- Now pour oil into the open edge.

- With a stopwatch, record how long it takes the oil temperature to rise to seal at the end of the tube.

- If it reaches the end, you should remove the seal and record how long it takes to read.

- The longer the oil takes to rise and fall, the more dense of oil is.

What Is The Viscosity Of Hydraulic Oil 68:

ISO 68 hydraulic oils have a viscosity similar to SAE 20W at operating temperature. Yet, these hydraulic fluids are designed to maintain their ideal viscosity over an extreme temperature range. A more comprehensive temperature range provides a higher viscosity index number. The viscosity of hydraulic oil 68 is 68 CST.

Final Word:

Ultimately, your hydraulic oil viscosity will change due to problems with the hydraulic system. It can be the symptom of a big problem. Because of that, identifying the changes in hydraulic oil is an essential part of ongoing maintenance. And you can acquire it through oil analysis as part of routine service.

Without it, by professional check, your correct viscosity level can avoid costly changes in service. However, that ensures your hydraulic systems operate at their best with minimal wear and tear. Overall, we hope you can understand how to check the viscosity of hydraulic oil from this article. We also hope you can test your home’s hydraulic viscosity ideally.

RELATED: