Oil analysis programs can help to save your business money. If you can test your lubricants and oil regularly it can maintain your proactive program. Also, regular oil testing can help you to identify pollution problems, and decrease product waste. Besides this, it also can avoid any expensive component repairs and breakdowns.

If you think you need to know your company’s diesel engine oil analysis results, that’s great. Determining the setup for your component and maintenance needs time. We can help you to set a schedule for regular testing and sampling. Then you can get a report complete of recommendations for your company or business. Let’s go to know below how to interpret diesel engine oil analysis results.

Diesel Engine Oil Analysis Interpretation:

Due to oil analysis, you can check oil quality, condition, pollution, and machine wear. When an abnormality is detected, you can know what steps to take to correct the main cause.

Ideally, it would help if you analyzed a sample of the used oil after each oil change and for each piece of equipment. A regular oil analysis program allows you to make a database of an engine’s historical behavior. Let’s discuss some points on, why should you focus on oil analysis:

Early-warning system

Think of oil analysis as an early-warning system. Is there extra diesel fuel in the oil? You should check your fuel system. What about your traces of coolant? Your cooling system also may need to be checked. Is there too much dirt or grime? Maybe you’ve over-extended your drain gap.

In such cases, the lab can notice minor problems long before you do. So you need to do something before these triggers turn into engine damage.

Lower Costs:

The knowledge gained from a continuous oil analysis program can help:

● Optimize the oil drain gap

● Enhance component dependability

● Lower unscheduled downtime

● More accurately track operating efficiency

This powerful combination can help reduce your total operating costs.

Metal issues

The wear-metal analysis section may identify a mechanical engine problem that has no relation to your oil.

High levels of iron may indicate cylinder liner wear. You can identify any abnormal levels of metals and interpret them in the lab. And they can give you valuable information about your engine.

Another oil analysis function is to tell you about your oil. For example, you will learn about its viscosity grade. Additionally, if it is too high, there may be some other type of pollution that is making the oil too thick.

Oil Sample Instructions

To get a proper oil sample and avoid pollution, consider the tips and tricks for collecting oil samples. After providing the instructions, you should follow them carefully.

● First, you need to start your engine and run it for 2 to 3 minutes. Basically, it allows the oil to be mixed so that it may have “settled”. And before collecting a sample it can be resuspended prior to sample collection. After taking your car for a drive, you can also collect a sample, but be careful working on a hot engine. To collect the sample, your oil doesn’t have to be at operating temperature.

● When collecting a sample from extracted oil, collect the sample from the middle of the stream. Do not collect the first oil bit for draining. It’s because it may not accurately depict the overall engine oil composition.

● Always clean your sampling equipment thoroughly before storing it and before using it again. Because only small amounts of oil are sampled, even small amounts of pollution will skew the results.

On the Other hand, you can follow Blackstone oil sample instructions or take services from them.

Diesel Engine Oil Analysis Cost:

With a professional testing service, you need to package your oil sample and mail it off. Many labs promise that they can give you the results within 24 hours of receiving the sample. But they take $50 per test. Some labs offer discounts on bulk and cost as little as $20 per test.

The benefits of having your oil tested by professional service are data, accuracy, and professional advice. A Blackstone service lab will often provide guidance if there are problems with the sample.

If you enjoy doing your own car maintenance, DIY oil analysis can be interesting. An at-home diesel engine oil analysis, kit usually costs less than $30 and is mostly straightforward.

Diesel In Oil Paper Test

Most people think that a paper towel test was an easy and quick way to identify a serious problem. Oil viscosity reduction from a mixture dropped on a paper towel by an enlarging ring identified the diesel presence. In several forums, this is claimed but finally, the test shows that this process is unqualified. So you should always try to do diesel engine oil sample analysis in a professional way. And to interpret the result perfectly you also should know the diesel engine oil analysis limits for the manufacturer.

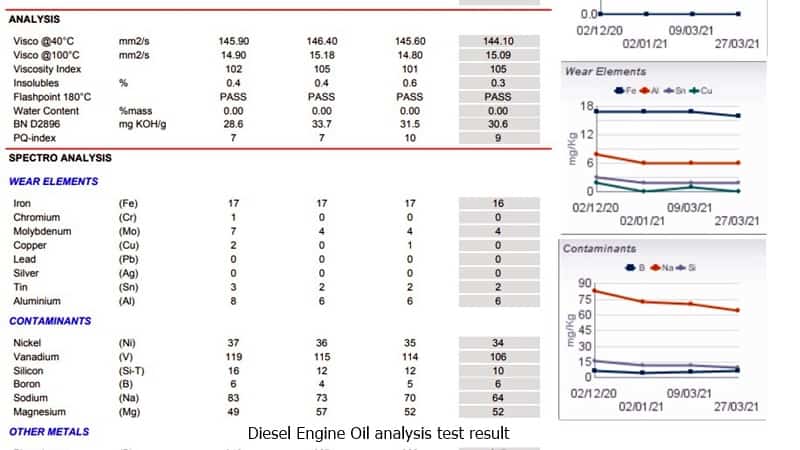

The Diesel Engine Oil Analysis Results

Your diesel engine oil analysis report is tough to understand. According to a recent survey by MachineryLubrication.com, approximately 32% of lubrication professionals don’t know how to interpret oil analysis reports. It’s a bit annoying. If you want to invest in oil analysis, understanding the reports is essential. Luckily we’re here to help you.

We know, an analysis will identify several chemicals and metals found in your engine oil. In addition, you also can know the diesel engine oil analysis acceptable limits.

Wear Metals:

Wear metals include iron, aluminum, chromium, bearings, camshafts, pistons, crankshafts, cylinder walls, and other engine moving parts. Values are usually given in ppm.

Fuel Dilution, % by volume :

Fuel dilution can detect the diesel fuel amount found in the engine oil. All engines will have some fuel dilution degree.

Excessive idle, bad ring seal, and leaking injectors all lead to extra fuel dilution. In addition, engine fitting and performance changes can contribute to a comprehensive degree of fuel dilution.

If fuel fluid exceeds acceptable limits, you need diagnostics to identify the root cause. Values are usually given in percentage by volume. Fuel dilution rates below 5% seem to be normal but may vary by engine manufacturer.

Exhaust soot, % by volume :

Like fuel dilution, exhaust soot enters the crankcase using blowby. Some exhaust soot in the engine oil is entirely normal, thus the reason oil rapidly turns black in diesel engines. Anything that creates black smoke out of the tailpipe (performance modifications, worn injectors, etc.) contributes to oil contamination. Values are typically given in percent by volume (volume of exhaust soot relative to the volume of engine oil). Exhaust soot tends to be relatively abrasive and accelerates engine wear.

Water, % by volume :

In the engine oil, water or engine coolant is the result of a failed seal, water pump O-ring(s), EGR cooler, or head gasket. Values are usually given in percentage by volume.

See: How To Detect Water In Oil

Oxidation, Viscosity, and Nitration :

The value of oxidation, nitration, and the viscosity of different temperatures are very important in diesel engine oil analysis results. They identify the current engine oil viscosity changes rate, contamination, and degree of degradation. This value indicates oil life or performance also.

TBN & TAN :

The total acid number & Total Base number are also very important parameters of the engine oil analysis tests. Especially the Total base number (TBN) indicates directly the oil drain interval of the diesel engine.

FAQ (Frequently Asked Questions) :

Q. How do you interpret oil analysis results?

You can interpret oil analysis results by reviewing the report, interpreting viscosity results, measuring metals, and undertaking wear limits.

Q. What should I look for in an oil analysis?

Make sure the report includes your name, machine manufacturer, lube type, and machine type. The report should also clearly state the condition of your machine and lubricant. The laboratory needs to have a rating system that informs you of normal, threshold, and critical levels.

Q. What is the normal oil consumption on a diesel engine?

You can usually know this information in workshop manuals or by contacting the OEM directly. The usual engine oil consumption ranges from 0.25% – 0.5% in proportion to the actual fuel consumption for diesel trucks.

Final Word :

Hope you have learned a lot about diesel engine oil analysis results from this article, so now you will able to check the important parameters of oil analysis and act accordingly.